Rinku Engineers (India) is a premier Pump Accessories Manufacturer and a comprehensive source for high-quality industrial components. We specialize in the precision engineering of critical spare parts that ensure the longevity, efficiency, and peak performance of industrial pumping systems. Based in Gujarat, our manufacturing facility supports diverse industries by providing durable solutions for routine maintenance and complex overhauls of centrifugal and process pumps.

Product Overview

In the demanding world of industrial fluid handling, the use of genuine, high-precision components is vital to prevent unplanned downtime and catastrophic equipment failure. As a leading Pump Spare Parts Manufacturer, Rinku Engineers provides an extensive inventory of components designed to meet or exceed original equipment specifications.

Our range is fully compatible with centrifugal, process, slurry, and specialized chemical pumps. To ensure reliability in aggressive environments, we offer these parts in a vast array of metallurgies and polymers, specifically selected to resist corrosion, erosion, and extreme thermal stress.

Major Pump Accessories & Spare Parts Offered

We manufacture a wide spectrum of components to support the entire lifecycle of your rotating equipment:

- Hydraulic Components: Precision-cast pump casings and dynamically balanced impellers for optimal flow.

- Drive Components: High-tensile shafts and protective shaft sleeves to prevent wear on core assemblies.

- Sealing Systems: Stuffing boxes, gland packings, high-performance mechanical seals, and specialized seal rings.

- Support Assemblies: Robust bearing frames, bearing housings, and protective covers.

- Hardware & Fasteners: Precision-machined lock nuts, adapters, and shaft keys.

- Static Seals: A full range of lantern rings, O-rings, and oil seals in various elastomeric grades.

Material of Construction (MOC)

The choice of material is fundamental to the performance of any spare part. We offer components in the following materials, tailored to your specific fluid type, temperature, and pressure requirements:

| Material Category | Specific Materials / Grades |

| Ferrous Metals | Cast Iron (CI), Cast Steel (CS) |

| Stainless Steels | SS 304, SS 316, SS 316L |

| Specialty Alloys | CD4MCu, Alloy-20, Hastelloy B & C |

| Thermoplastics | PTFE, Glass-filled PTFE (GFT) |

| Elastomers | Buna-N, Viton, EPDM |

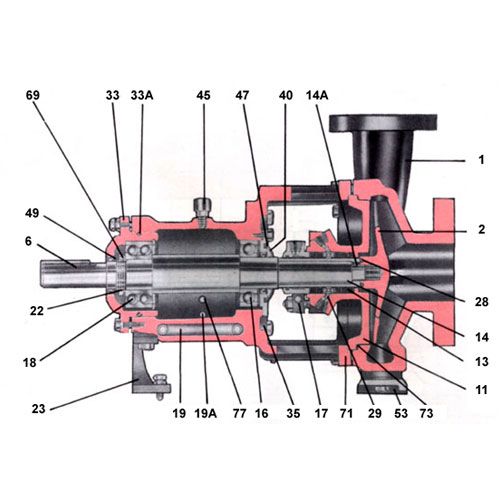

Part List and Material of Construction

| Part No. | Part Name | Cast Iron | Cast Steel | SS316 | SS304 | CD4MCu | Alloy-20 | Hastalloy B&C |

| 1 | Casing | Cast Iron | Cast Steel | SS316 | SS304 | CD4MCu | Alloy-20 | Hast alloy B&C |

| 2 | Impeller | Cast Iron | Cast Steel | SS316 | SS304 | CD4MCu | Alloy-20 | Hast alloy B&C |

| 6 | Shaft | SAE-4140 | SS316 | |||||

| 11 | Stuffing Box Cover | Cast iron | Cast Steel | SS316 | SS304 | CD4MCu | Alloy-20 | Hastalloy B&C |

| 13 | Stuffing Box Packing | TIWA | PTFE | |||||

| 14 | Shaft Sleeve | SS410 | SS316 | SS316 | CD4MCu | Alloy-20 | Hastalloy B&C | |

| 14 A | Drive Pin | SS410 | ||||||

| 16 | Bearing Inboard | STEEL | ||||||

| 17 | Gland Quench | SS316 | Alloy-20 | Hast Alloy | ||||

| 17 A | Gland Packing | TIWA | ||||||

| 18 | Bearing Outboard | STEEL | ||||||

| 18 A | Retaining Ring | STEEL | ||||||

| 19 | Bearing Frame | CAST IRON | ||||||

| 19 A | Bearing Oil Drain Plug | STEEL | ||||||

| 22 | Bearing Lock Nut | STEEL | ||||||

| 23 | Bearing Frame Foot | CAST IRON | ||||||

| 28 | Impeller Seal Ring | PTFE | ||||||

| 29 | Lantern Ring | Glass Filled PTFE | ||||||

| 33 | Bearing Housing | CAST IRON | ||||||

| 33 A | O-ring | Buna Rubber | ||||||

| 35 | Bearing Cover Inboard | CAST IRON | ||||||

| 35 A | Gasket-Bearing Cover IB | Asbestos | ||||||

| 37 | Bearing Cover-OB | CAST IRON | ||||||

| 37 A | Gasket-Bearing Cover -OB | Asbestos | ||||||

| 38 | Shaft Sleeve Gasket | Asbestos | ||||||

| 40 | Deflector | SS304 | ||||||

| 45 | Breather | STEEL | ||||||

| 46 | Key – Coupling | STEEL | ||||||

| 47 | Oil Seal IB | Buna Rubber | ||||||

| 49 | Oil Seal-OB | Buna Rubber | ||||||

| 53 | Casing Foot | CAST IRON | ||||||

| 69 | Bearing Lock Washer | STEEL | ||||||

| 71 | Frame Adapter | CAST IRON | ||||||

| 73 | Casing Gasket | Asbestos or PTFE | ||||||

| 77 | Constant Level Oiler | PLASTIC / AL | ||||||

Key Features & Advantages

- Precision Manufacturing: Produced using advanced CNC machining to ensure perfect interchangeability.

- High Dimensional Accuracy: Tight tolerances ensure a seamless fit, reducing vibration and noise.

- Corrosion and Wear Resistance: Material selections targeted at aggressive chemical and abrasive slurry media.

- Extended Operational Life: Enhanced metallurgy leads to longer intervals between maintenance cycles.

- Ease of Installation: Standardized designs allow rapid replacement and reduced downtime.

- Industrial Resilience: Engineered to perform under high-pressure and high-temperature conditions.

Industrial Applications

- Process Engineering: Specialized parts for centrifugal process pumps in refineries.

- Chemical & Pharma: Corrosion-resistant components for aggressive fluid transfer.

- Waste Management: Durable spares for slurry, mud, and ETP/STP pumping systems.

- Energy Sector: Spares for circulation and condensate pumps in power generation.

- Petrochemicals: High-integrity seals and shafts for volatile fluid handling.

Why Choose Rinku Engineers

- Rigid Quality Control: Every accessory and spare part undergoes thorough dimensional and material inspection.

- Extensive Material Portfolio: One of the widest ranges of MOCs to handle any industrial fluid.

- Deep Application Expertise: Engineering support to select the right part based on operating challenges.

- Rapid Availability: Streamlined manufacturing for timely delivery of critical spares and reduced inventory costs.

Conclusion

Rinku Engineers (India) is your trusted Pump Accessories & Pump Spare Parts Manufacturer and Supplier in Ahmedabad, Gujarat. We are dedicated to delivering the high-integrity components required for uninterrupted industrial performance. By combining metallurgical expertise with precision engineering, we ensure that your fluid handling systems remain efficient and reliable. For high-quality Pump Accessories Supplier in Ahmedabad services, rely on our proven range of industrial spares.

Centrifugal Pump Accessories | Centrifugal Process Pump Spare Parts | Industrial Process Pumps Accessories – Manufacturers & Suppliers | Circulation Pump | Mud Pump / Refinery Pump | Condensate Pump | Slurry Pump | End Suction Centrifugal Process Pump Spares In India