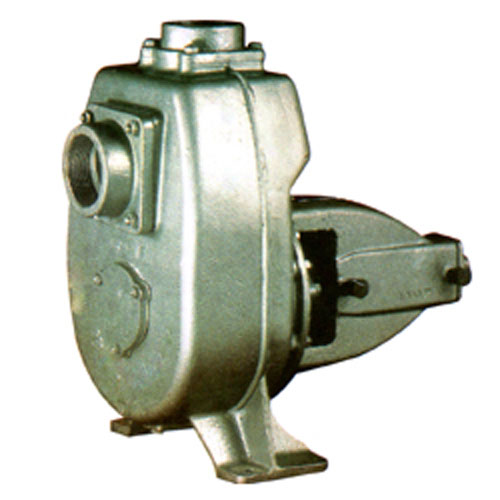

AYUSH Self Priming Pump – Self Priming Pump Manufacturer in Ahmedabad

Rinku Engineers (India) is a premier Self Priming Pump Manufacturer specializing in high-performance centrifugal solutions designed for challenging suction conditions. The AYUSH Self Priming Pump series is engineered to lift liquids from levels significantly below the suction port, eliminating the need for manual priming or external assistance. Built for durability and ease of use, these pumps are the preferred choice for industrial, civil, and utility operations across Gujarat and beyond.

A self-priming pump is a specialized type of centrifugal pump designed to overcome the problem of air binding by mixing air with water to create a pumpable fluid. AYUSH Self Priming Pumps feature a unique casing design that enables the unit to automatically evacuate air from the suction line.

This capability ensures reliable performance in applications involving intermittent pumping or where the liquid source is located at a lower elevation than the pump itself. By maintaining a constant state of readiness, these pumps optimize operational uptime in critical lifting conditions.

How Self Priming Pump Works?

Types of Self Priming Pump

The AYUSH range primarily utilizes Dynamic Centrifugal Self-Priming technology. These units utilize a high-efficiency impeller and a precision-engineered diffuser to manage fluid movement.

As the impeller rotates, it converts mechanical energy from the motor into velocity energy. The diffuser then converts this velocity into pressure, driving the fluid through the discharge port. This centrifugal force is what allows the pump to manage both the air-handling priming phase and the high-volume fluid transfer phase with equal efficiency.

Dynamic Pump

- A dynamic pump transfers the fluid by increasing its pressure as it passes through the impeller and diffuser of the pump. The impeller increases the speed of the fluid and the diffuser converts this speed into pressure energy. It uses centrifugal force to transfer the fluids.

- A dynamic pump further divides into the below-given types:

- Centrifugal Pumps

- Special Effect Pumps

Why Choose Rinku Engineers

Rinku Engineers (India) has earned its reputation as a dependable Self Priming Pump Supplier in Ahmedabad through a steadfast commitment to quality and engineering precision.

- Manufacturing Expertise: High-grade materials and advanced casting techniques for harsh industrial environments.

- Robust Design: Built for longevity with wear resistance and low-vibration performance.

- Application Engineering: Support to select the right pump size and MOC for fluid specific gravity and viscosity.

- Reliable After-Sales Service: Genuine spare parts availability and technical support for uninterrupted operations.

Rinku Engineers (India) stands as a trusted Self Priming Pump Manufacturer and Supplier in Ahmedabad, Gujarat. Our AYUSH series provides a robust, low-maintenance solution for industries requiring efficient liquid lifting and dewatering capabilities. By integrating advanced centrifugal technology with a user-friendly design, we deliver pumping systems that guarantee reliability in the most demanding civil and industrial applications.