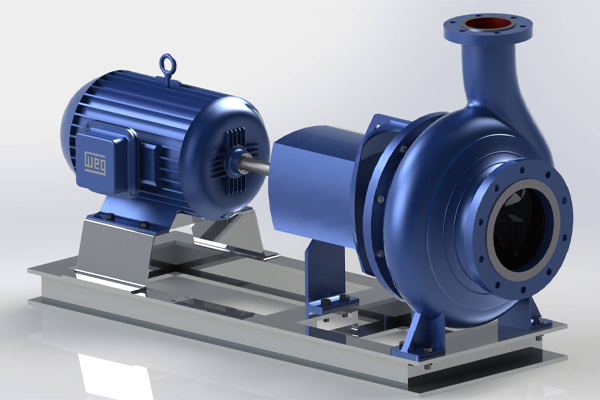

In many industries—from chemicals, petrochemicals, pharmaceuticals to water treatment end suction centrifugal process pumps are among the most widely used pump types for transferring liquids with reliability and efficiency. An end suction design implies that the fluid enters the pump axially at the “end” or front side and is discharged radially through the volute or diffuser. This straightforward layout makes these pumps compact, easy to maintain, and cost-effective. They can handle a wide range of liquid types (clean water, acids, alkalis, solvents, etc.), provided materials of construction and sealing are selected appropriately. Rinku Engineers offers high-performance end suction process pumps built with rigorous attention to hydraulic design, balanced impellers, and versatile material options (CI, SS, alloys) so that users can match the pump to their process needs.

One of the strong advantages of Rinku’s end suction pumps is their back pull-out design, which allows maintenance without disturbing the piping—a valuable feature for industrial uptime. The pumps are dynamically balanced, built to handle moderate pressures and heads (e.g. up to 100–150 m depending on model) and support a variety of mechanical seals or packing options for leak control. These models conform to standard dimensions (often per DIN 24255 in horizontal single-stage designs) and come in multiple sizes and capacities, making them suitable for many sectors. With Rinku’s experience in process pumps, users get a dependable solution for fluid transfer, circulation, and process integration with minimal downtime risk.

Frequently Asked Questions (FAQs)

What are typical limitations or challenges of end suction pumps?

They may have limited suction lift (require good NPSH), less effective for high heads (multi-staging may be needed), sensitivity to cavitation, and potential for clogging with suspended solids.

How does Rinku Engineers ensure reliability in their end suction pumps?

By employing balanced impellers, rigorous quality control, proper material selection (CI, stainless steel, alloys), back pull-out design, and multiple sealing options.

How should I choose the right end suction pump for my application?

Consider flow rate, head, fluid properties (viscosity, corrosivity), temperature, required materials, NPSH (net positive suction head), and whether you need back pull-out or specific sealing types. Match pump curves and ensure suitable safety margins.

What exactly is an “end suction” centrifugal pump?

It’s a type of centrifugal pump where fluid enters the pump at the front (end) and is expelled radially outward. The suction is axial and the discharge is peripheral.

What are the benefits of end suction design versus other pump types?

Polypropylene has a melting/softening threshold, so PP pumps are typically limited to moderate temperatures (often up to ~ 70 °C or somewhat higher depending on grade)

What industry fluids can these pumps handle?

They are suitable for water, various chemicals (acids, alkalis, solvents), clean liquids, and moderate slurries—depending on the materials of construction and sealing used.