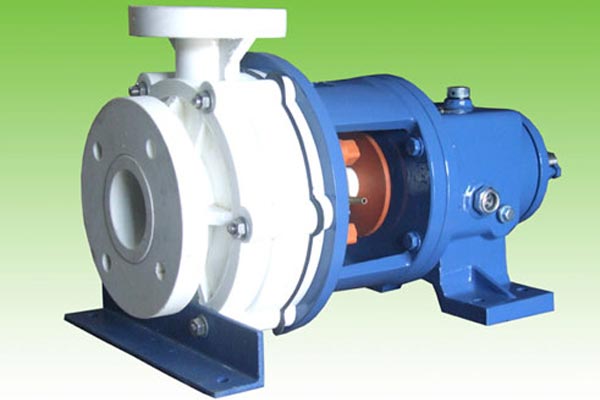

In today’s fast-evolving industrial landscape, companies across chemical, pharmaceutical, food processing, and water treatment sectors are searching for reliable solutions that can handle corrosive and abrasive fluids with ease. Traditional metal pumps, though durable, often struggle with acids, alkalis, and aggressive chemicals that cause frequent wear and tear. This is where Polypropylene Process Pumps are proving to be a game-changer. Known for their excellent chemical resistance, lightweight build, and cost-effectiveness, these pumps ensure smooth and safe fluid transfer without the risk of corrosion. They are ideal for handling hydrochloric acid, caustic soda, sulphuric acid, solvents, and other harsh fluids that demand a material resistant to chemical attack. By adopting polypropylene pumps, industries can reduce downtime, minimize leakages, and achieve higher operational safety while optimizing energy consumption.

At Rinku Engineers, we design and manufacture high-performance Polypropylene Process Pumps that cater to a wide range of industries facing chemical-handling challenges. Our pumps are built with precision engineering to provide high efficiency, longer life, and minimal maintenance even in the toughest operating environments. With growing emphasis on cost savings, safety, and sustainability, more businesses are shifting towards polypropylene pumps as a future-ready investment. Whether it’s for chemical plants, effluent treatment, pharmaceuticals, or textile dyeing units, our polypropylene pumps ensure durability, reliability, and smooth performance. As industries continue to prioritize efficiency and environmental safety, polypropylene process pumps will remain in high demand, making them the backbone of modern fluid-handling systems.

Frequently Asked Questions (FAQs)

Can polypropylene pumps handle high-temperature fluids?

Yes, they can handle a wide temperature range, though they are best suited for low to moderate temperatures in chemical applications.

How do polypropylene pumps reduce operational costs?

They last longer in corrosive environments, minimize downtime, and require fewer repairs, thereby lowering overall maintenance and replacement costs.

Why choose Rinku Engineers for polypropylene process pumps?

Rinku Engineers provides precision-engineered, durable, and industry-tested polypropylene pumps designed to deliver efficiency, reliability, and long service life.

What are Polypropylene Process Pumps?

Polypropylene Process Pumps are non-metallic pumps made from polypropylene material, designed for handling corrosive and abrasive chemicals safely.

Why are polypropylene pumps better than metal pumps?

They resist corrosion from acids and alkalis, are lightweight, cost-effective, and require less maintenance compared to traditional metal pumps.

Which industries use Polypropylene Process Pumps?

They are widely used in chemical plants, pharmaceuticals, effluent treatment plants, food processing, and textile industries.