In many process industries—petrochemicals, lubricants, inks, adhesives, food & beverage, and chemical transfer—rotary gear pumps are indispensable for delivering precise, pulsation-free flow of viscous or shear-sensitive fluids. Unlike centrifugal pumps, gear pumps produce flow proportional to speed, making them excellent for metering, dosing, or maintaining constant flow at varying pressures. Rinku Engineers, with its foundation in fluid-handling solutions, positions itself as a leading manufacturer of industrial rotary gear pumps in Ahmedabad, India. Their AYUSH Gear Pump (AFGP / AFJGP series) features heavy duty construction, herringbone rotor design to eliminate side thrust, floating gear architecture for uniform load distribution, and optional steam jacketing for thermal control. rinkuengineers.com The company also offers AGP / External Gear Pump models suited for lower viscosity fluids with compact and reversible designs.

Rinku’s pumps are built for durability and flexibility. They support capacities up to 125 m³/hr, sizes from ½″×½″ to 6″×6″, and RPM up to 1400 for certain models. rinkuengineers.com Material options include cast iron, stainless steel (SS-316), and specialized alloys depending on fluid compatibility. rinkuengineers.com Because of their design—tight internal clearances, robust rotor geometry, and careful sealing—they handle viscous oils, fuels, chemical feeds, and even gear oils reliably. Rinku also emphasizes low leakage paths by design to improve volumetric efficiency, further boosting operational cost savings and performance

FAQs on Industrial Rotary Gear Pumps

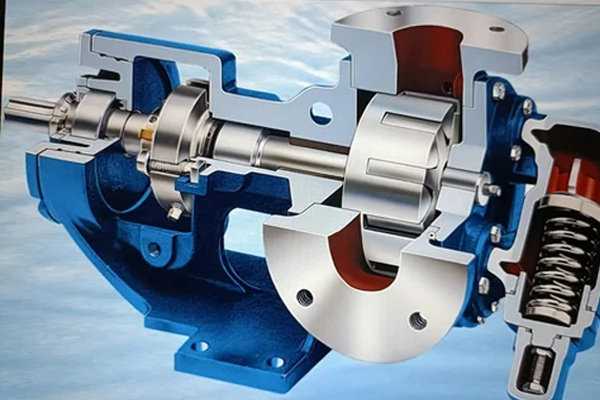

What is a rotary gear pump and how does it work?

A rotary gear pump is a type of positive displacement pump where two intermeshing gears rotate inside a casing. Fluid is trapped between gear teeth and the housing, carried from the inlet side to the outlet side, and discharged as the gears mesh. The result is smooth, steady flow even under varying pressure.

What are the major advantages of using rotary gear pumps?

-

Pulsation-free, smooth flow

-

Precise volumetric metering

-

Ability to handle viscous fluids

-

Self-priming capability (in many designs)

-

Reversible flow in many gear pump models

What limitations or challenges come with rotary gear pumps?

-

They require tight tolerances; wear or damage can degrade performance

-

Not ideal for high solids or abrasive fluids

-

Heat generation at high speeds or tight clearances

-

Viscosity and temperature sensitivity require careful matching to pump specs

What parameters must be considered when selecting a gear pump?

Consider required flow rate (m³/hr or LPM), differential pressure (head), fluid viscosity and temperature, compatibility with materials of construction, rotational speed (RPM), seal type (mechanical, lip seals, etc.), and allowable leakage (efficiency).

What applications are typical for industrial rotary gear pumps?

They are widely used in lubrication systems, fuel transfer, additive dosing, chemical metering, oil refining, paints & coatings, adhesives, food oils, and hydraulic circuits.

Why is Rinku Engineers a strong choice as a gear pump manufacturer?

Rinku has decades of experience in pump design and manufacturing, offers multiple pump series (AYUSH AFGP / AFJGP, AGP external series), supports custom materials (CI, SS-316) and capacities up to 125 m³/hr, and emphasizes design features like low leakage, heavy duty rotor geometry, and thermal jacketing options