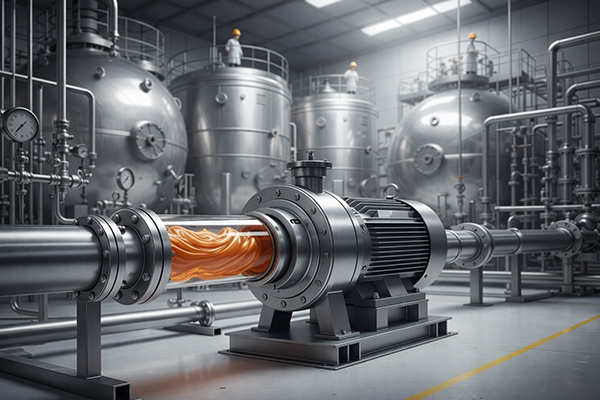

In the world of manufacturing and engineering, moving liquids is a daily task. While moving water is easy, moving thick, sticky, or heavy liquids is much harder. Imagine trying to drink a thick milkshake through a straw compared to drinking water. It takes much more effort. factories face this same problem when they need to move oil, honey, paint, or chemical glue. A regular water pump cannot handle these thick fluids. It might get stuck or break down. This is why industries rely on a special machine called the Rotary Gear Pump.

These pumps are the “workhorses” of the industrial world. They are strong, simple, and very reliable. This article explains what these pumps are, why they are so popular, and which industries depend on them the most.

What Is a Rotary Gear Pump?

A rotary gear pump is a type of machine used to move fluids. Engineers call it a “positive displacement pump.”

Here is the simple explanation:

Most pumps push water using a spinning fan (like a propeller). A gear pump is different. It uses rotating gears (wheels with teeth) to grab the liquid and move it physically from one side to the other.

How Rotary Gear Pump Works

The Inlet

The liquid enters the pump.

The Trap

Inside the pump, there are two gears turning. The liquid gets trapped in the spaces between the gear teeth.

The Journey

As the gears turn, they carry the trapped liquid around the outside of the pump casing.

The Outlet

On the other side, the gears come back together (mesh). This squeezes the liquid out of the pump and into the pipe.

Think of it like a revolving door at a hotel. People (the liquid) enter the door, move around the circle, and are pushed out into the lobby. They cannot go backward.

Why Industries Prefer Rotary Gear Pump

Factory owners and engineers choose rotary gear pumps for several specific reasons:

Top Industries That Use Rotary Gear Pumps

Oil & Petroleum Industry

The oil industry is the biggest user of rotary gear pumps. Almost every stage of oil production uses them.

- The Challenge: Crude oil and lubricants are very thick. They are also vital for energy. Moving them requires a pump that won’t get clogged.

- How They Use Gear Pumps:

- Transfer: Moving crude oil from storage tanks to tanker trucks.

- Lubrication: Pumping clean oil into engines to keep machinery running smoothly.

- Bitumen and Tar: Moving the hot, black sticky stuff used to make roads.

- Why It Works: Oil is a natural lubricant. As it flows through the pump, it oils the gears. This means the pump protects itself while it works, allowing it to last for years.

Chemical Processing Industry

Chemical factories handle dangerous, expensive, and sticky fluids. Safety and accuracy are the top priorities here.

- The Challenge: Chemicals like resins, glues, and acids must be moved carefully. You cannot spill them, and you often need to measure exactly how much you are pumping.

- How They Use Gear Pumps:

- Metering: Because gear pumps move a specific amount of fluid with every turn, they are used to measure chemicals precisely.

- Mixing: Pumping component A and component B into a mixer to create a new product, like glue or plastic.

- Why It Works: These pumps can be made from stainless steel or special alloys. This stops the chemicals from eating away at the metal (corrosion).

Food & Beverage Industry

Making food on a large scale is a heavy job. The liquids in a food factory are often very thick and sweet.

- The Challenge: Imagine trying to pump peanut butter or cold chocolate. It is very hard to move. Also, the pump must be perfectly clean so the food is safe to eat.

- How They Use Gear Pumps:

- Confectionery: Pumping liquid chocolate, fondant, and cream fillings.

- Bakery: Moving dough, batter, butter, and vegetable oils.

- Drinks: Pumping thick fruit pulps, syrups, and molasses for making sodas.

- Why It Works: Gear pumps move the food gently. A fast-spinning fan pump might whip air into the food or damage it. A gear pump moves it smoothly without ruining the texture.

Paint, Ink, and Coating Industry

If you look at a painted wall or a printed newspaper, a gear pump helped make it.

- The Challenge: Paint and ink are viscous (thick) and sticky. They dry quickly if exposed to air.

- How They Use Gear Pumps:

- Manufacturing: Moving the paint from large mixing vats into the small cans sold in stores.

- Printing: Pumping ink from a reservoir onto the rollers of a printing press.

- Why It Works: A steady flow is critical. If the pump “pulses,” the paint will splash or the printing will be uneven. Gear pumps provide the smooth flow needed for a perfect finish.

Pharmaceutical Industry

This industry makes medicines, soaps, and lotions.

- The Challenge: Hygiene is the most important factor. The pump must be easy to clean to prevent bacteria.

- How They Use Gear Pumps:

- Cosmetics: Filling bottles with shampoo, lotion, and face cream.

- Medicine: Pumping ointments and gels into tubes.

- Why It Works: Gear pumps are very accurate. They ensure that every tube of medicine has exactly the right amount of product inside.

Manufacturing & Machinery (Hydraulics)

This category covers almost all heavy machines, from tractors to factory robots.

- The Challenge: Big machines have many moving metal parts. If these parts rub against each other dry, they will overheat and break.

- How They Use Gear Pumps:

- Lube Oil Circulation: Small gear pumps are built inside engines to keep oil flowing over the moving parts.

- Hydraulics: Using oil pressure to lift heavy loads (like a dump truck lifting its bed).

- Why It Works: They are compact. A small gear pump can create high pressure, which is perfect for fitting inside cramped engine spaces.

Common Applications Across Industries

Even though the industries are different, the tasks are often similar. Here is a summary of common jobs for these pumps:

Fuel Transfer

Moving diesel or gasoline from one tank to another.

Loading / Unloading

Filling up tanker trucks or trains.

Circulation

Keeping hot fluids moving through pipes.

Spraying

Pushing hot tar or asphalt through spray nozzles.

Comparison Table: Industry Usage

Here is a simple table to compare how different sectors use this technology.

| Industry | Typical Fluids Handled | Why Gear Pump? | Key Benefit |

| Petroleum | Crude Oil, Diesel, Lube Oil | Fluid is thick and oily | Long pump life due to self-lubrication |

| Food & Bev | Chocolate, Honey, Butter | Fluid is delicate and sticky | Gentle handling maintains food quality |

| Chemical | Resins, Glues, Acids | Needs exact measurements | High accuracy for mixing |

| Paint & Ink | Varnish, Enamel, Ink | Fluid is very sticky | Smooth, non-pulsing flow |

| Road Works | Asphalt, Tar, Bitumen | Fluid is hot and heavy | Handles high heat and viscosity well |

Benefits of Using Rotary Gear Pump in Industry

Why do engineers choose rotary gear pumps over other types?

- Efficiency with Thick Fluids

This is the biggest advantage. As the liquid gets thicker, the gear pump actually becomes more efficient. The thick liquid seals the gaps between the gears, preventing leaks.

- Compact and Powerful

You do not need a giant machine to get a lot of power. A small gear pump can fit in tight spaces but still move liquid with great force.

- Low Maintenance

Because there are no complex valves or springs inside, maintenance is easy. Usually, you only need to check the seals and bearings. This saves the factory money on repairs.

- Predictable Performance

If you know how fast the gears are turning, you know exactly how much liquid is moving. This predictability is vital for automated factories.

How to Choose the Right Rotary Gear Pump for Your Industry

If you need to select a pump, consider these four simple factors:

1. Viscosity (Thickness): How thick is the fluid? If it is very thick (like peanut butter), you need a pump with large teeth that turns slowly. If it is thin (like diesel), the pump can turn faster.

2. Temperature: How hot is the fluid? Metal expands when it gets hot. For hot tar, you need a pump designed with extra “clearance” (space) inside so the gears don’t get stuck when they expand.

3. Chemical Compatibility: Will the fluid eat the metal? For acids or food, use Stainless Steel. For oil, Cast Iron is usually fine and cheaper.

4. Pressure Needs: How far do you need to push the liquid? If you are pumping through a very long pipe, you need a pump rated for high pressure.

Frequently Asked Questions (FAQs)

You can, but it is not recommended. Water is too thin and does not lubricate the gears. Using it for water will make the gears wear out very fast.

This is very bad. The gears need the liquid to slide against each other smoothly. If the pump runs without liquid, the metal parts will rub, get hot, and melt or break.

No. Gear pumps have very tight spaces between the teeth. A stone or piece of metal will jam the gears and break the shaft. The liquid must be clean.

If used correctly with clean oil, they can last for decades. They are known for their long life.

A loud noise usually means the pump is “starving.” This happens when the inlet pipe is blocked, or the liquid is too cold and thick to flow into the pump easily.

Yes. Since the design is simple, a technician can usually open it up, replace the worn gears or seals, and put it back together quickly.

External pumps use two gears side-by-side. Internal pumps use one gear inside another. Internal pumps are better for delicate liquids (like shampoo), while External pumps are better for heavy-duty jobs (like hydraulics).

Conclusion

Rotary gear pumps may look like simple blocks of metal, but they are essential to our modern life. They keep our cars running with fuel, they help make the food we eat, and they ensure our homes are painted and heated.

For any industry that deals with thick, heavy, or sticky liquids, the rotary gear pump is the first choice. Its ability to work hard, last long, and handle difficult fluids makes it one of the most important tools in the industrial world. Whether you are a student or a business owner, understanding this pump helps you understand how the manufacturing world moves.

If you are looking for reliable and high-performance rotary gear pumps for your industry, Rinku Engineers is here to help. With strong manufacturing expertise and quality-driven solutions, we provide rotary gear pumps designed to meet demanding industrial applications. Contact Rinku Engineers today to discuss your pumping requirements.