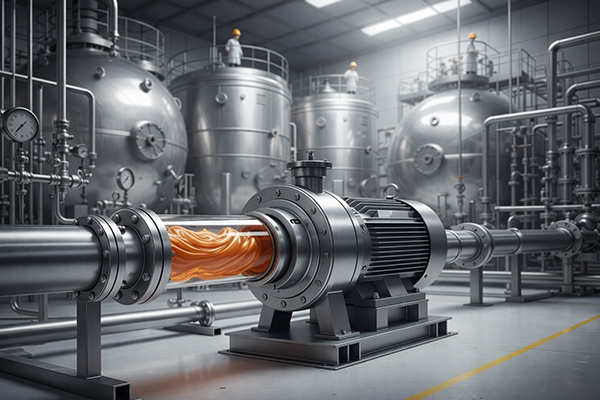

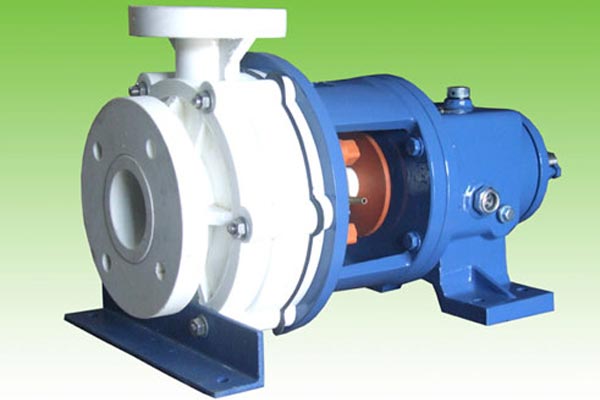

Applications of Multi Spring Mechanical Seals in Process Industries

Process industries are businesses that turn raw materials into products using heat, chemical reactions, or mixing. Examples include plants that make medicine, refine oil, or clean water. In these factories, pumps are used to move liquids through pipes. For these pumps to work correctly, they need to be sealed perfectly. If a seal fails, the…